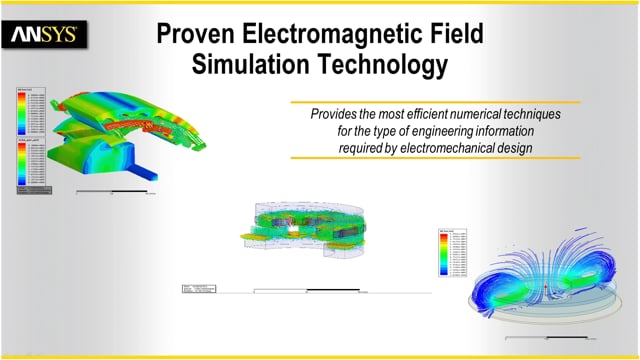

Low Frequency Electromagnetic Field Simulation

ANSYS Maxwell is a premier low-frequency electromagnetic field simulation solution which uses the highly accurate finite element method to solve static, frequency-domain, and time-varying electromagnetic and electric fields. Maxwell includes a wide range of solution types for a complete design flow for your electromagnetic and electromechanical devices.

Solvers included with ANSYS Maxwell:

- Magnetic Transient — Nonlinear analysis with:

- Rigid motion — rotation, translational, non-cylindrical rotation

- External circuit coupling

- Permanent magnet demagnetization analysis

- Core loss computation

- Lamination modeling for 3-D

- Magnetic vector hysteresis

- Magnetoresistive modeling in 2-D/3-D

- AC Electromagnetic — Analysis of devices influenced by skin/ proximity effects, eddy/displacement currents

- Magnetostatic — Nonlinear analysis with automated equivalent circuit model generation

- Electric Field — Transient, electrostatic/current flow analysis with automated equivalent circuit model generation

Automatic, Adaptive Meshing

A key benefit of Maxwell is its automatic adaptive meshing techniques, which require you to specify only the geometry, material properties and the desired output to obtain an accurate solution. The meshing process uses a highly robust volumetric meshing technique and includes a multithreading capability that reduces the amount of memory used and accelerates time to solution. This proven technology eliminates the complexity of building and refining a finite element mesh and makes advanced numerical analysis practical for all levels of your organization.

High-Performance Computing

Adding an ANSYS Electronics HPC license to Maxwell opens a world of bigger, faster and higher-fidelity simulations. ANSYS goes well beyond simple hardware acceleration to deliver groundbreaking numerical solvers and HPC methodologies that are optimized for single multicore machines and scalable to take advantage of full cluster power.

Time Decomposition Method

The Time Decomposition Method delivers computational capacity and speed for the full transient electromagnetic field simulations required for electric motors, planar magnetics and power transformers. This patent-pending technology enables you to solve all time steps simultaneously instead of sequentially, while distributing the time steps across multiple cores, networked computers and compute clusters. The result is a phenomenal increase in simulation capacity and speed.

Multithreading

Take advantage of multiple cores on a single computer to reduce solution time. Multithreading technology speeds up the initial mesh generation, direct and iterative matrix solves, and field recovery.

Spectral Decomposition Method

The majority of electromagnetic simulations require results such as near field, far field and s-parameter data over a range of frequencies. Spectral decomposition distributes the multiple frequency solution in parallel over compute cores to accelerate frequency sweeps. You can use this method in tandem with multithreading. Multithreading speeds up extraction of each individual frequency point, while spectral decomposition performs many frequency points in parallel.

System and 3D FEA Modelling

Maxwell includes ANSYS Simplorer Entry, a model-limited, multidomain simulation software package for the design of complex electromechanical, power electronic and drive systems. Simplorer employs a schematic approach to represent and couple electrical, magnetic, mechanical, hydraulic, thermal and other multidomain models to rapidly and accurately simulate circuit and systems behavior.

Simplorer offers multiple modeling techniques such as circuits, block diagrams and state machines. It also supports an array of modeling languages, including VHDL-AMS, SML (Simplorer Standard Language), Modelica and C/C++. All these modeling techniques can be used concurrently, enabling you to create analog, digital and mixed-signal multidomain system designs.

ANSYS Maxwell can uniquely generate high-fidelity FEA component models to be included in Simplorer so that you can verify that the electromagnetic performance meets overall system requirements. Embedded software from SCADE Suite can also be incorporated into Simplorer to validate electronic control systems using Hardware-in-the-Loop or Software-in-the-Loop simulation.

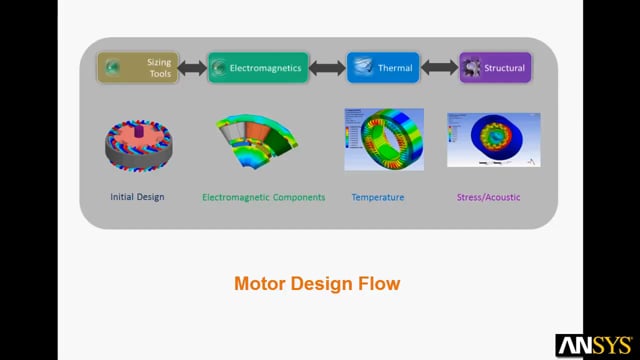

Multiphysics Analysis

Maxwell’s electromagnetic field solvers are linked through ANSYS Workbench to the complete ANSYS engineering portfolio. By coupling the electromagnetic field solution with other solvers, you can examine coupled physics phenomena and achieve the highest fidelity solution to eliminate reliability problems and design safe and effective products. The ANSYS platform manages the data transfer between physics solutions and handles solver interactions, so you can easily set up and analyze complex coupled-physics behaviors such as:

- Electromagnetic–Structural with deformed mesh feedback

- Electromagnetic–Structural with stress and strain feedback on magnetic properties

- Electromagnetic–Fluids

- Electromagnetic–Structural–Fluids

- Electromagnetic–Structural Dynamics–Acoustic

Expert Design Interfaces

Maxwell includes two specialized design interfaces for electric machines and power converters.

RMxprt – Rotating Electric Machines

RMxprt calculates machine performance, makes initial sizing decisions and performs hundreds of “what if” analyses in a matter of seconds. In addition to providing classical motor performance calculations, RMxprt automatically generates geometry, motion and mechanical setup, material properties, core loss, winding and source setup for detailed finite element analysis in Maxwell. In addition, RMxprt automatically generates geometry, corresponding material properties assignment, boundaries and excitation conditions for detailed electronics cooling simulation using CFD in ANSYS Icepak.

PExprt – Electronic Transformers and Inductors

PExprt’s template-based interface for transformers and inductors can automatically create a design from voltage waveform or converter inputs. The auto design process considers all combinations of core shapes, sizes, materials, gaps, wire types and gauges, and winding strategies to optimize the magnetic design. PExprt creates Maxwell models to evaluate the magnetic properties based on finite element analysis. This enables you to assess quantities such as flux density in the core and current density distribution in the windings.

Optimization and Parametric Modeling

Parameterization and optimization are key enablers for Simulation-Driven Product Development. Parametric analysis provides a thorough understanding of the design space based on your design variables, so that you can make better engineering decisions. Optimization algorithms enable the software to automatically find better designs. Parameterization and optimization capabilities available with Maxwell include:

Parametric analysis

- User-specified range and number of steps for parameters

- Automatic analysis of parameter permutations

- Automated job management across multiple hardware platforms and reassembly of data for parametric tables and studies

Optimization

- User-selectable cost functions and goal objectives, including:

- Quasi-Newton method

- Sequential nonlinear programming (SNLP)

- Integer-only sequential nonlinear programming

Sensitivity Analysis

- Design variation studies to determine sensitivities to:

- Manufacturing tolerances

- Material properties

Tuning

- User-controllable slide-bar for real-time tuning display and result

Statistical Analysis

- Design performance distribution versus parameter values

Advanced Electromagnetic Material Modelling

Accurately predicting performance of electric machines often depends on the operating temperature and loading history of its components. These effects can be accurately accounted for with Maxwell’s advanced material modeling capabilities.

Vector Hysteresis

ANSYS Maxwell employs a vector hysteresis model to accurately predict the minor loops and losses for soft and hard magnetic materials and permanent magnets. The model accounts for both isotropic and anisotropic materials, laminated and non-laminated structures, and the magnetic behavior of ferromagnetic materials when the magnetic operating point history has significant impact on the performance of such devices.

Temperature-Dependent Permanent Magnets

ANSYS Maxwell’s demagnetization analysis features enable you to study permanent magnet demagnetization characteristics extended into the third quadrant. External magnetic fields and heating can alter the magnetic properties of permanent magnets, leading to local demagnetization. You can combine these effects to accurately determine the performance of a machine.

Core Loss

Maxwell accurately computes core loss in magnetic materials. Electromagnetic degradation in laminate components and motor assemblies is difficult to predict because of the gap between virgin material data provided by the material supplier and the actual material performance when subjected to real operating conditions. Maxwell takes into account the feedback of the core-loss effect based on a unique algorithm that is predictable, reliable and easy to use.

Magnetostriction

Based on sequential load transfer couplings between ANSYS Maxwell and ANSYS Mechanical solvers, designers can model materials whose magnetic characteristics are strongly dependent on mechanical stress and strain. These effects cause energy loss due to frictional heating in ferromagnetic cores. The effect is also responsible for the low-pitched humming sound that can be heard coming from transformers, caused by oscillating AC currents, which produce a changing magnetic field. Similarly, for rotating electric machines, the reluctance forces and forces due to magnetostriction acting on the stator teeth are major causes of noise emission.

Design Automation and Customization

ANSYS enables you to develop tools to automate any design process requiring finite element analysis as a generic numerical method to accurately compute design performance. Custom automation also enables non-experts to use simulation correctly. Customization capabilities in Maxwell are based on open standards and well-documented interfaces. For example, ANSYS Python scripting tools were used to develop custom toolkits to automate the advanced designs of an electric machine and electric transformers.